In the world of precision mechanics, accuracy isn’t optional it’s critical. Whether you’re working in aerospace, automotive repair, heavy machinery maintenance, or manufacturing, torque wrench calibration is a non-negotiable part of ensuring safety, efficiency, and performance. When torque specifications are off, the consequences can range from inefficient performance to catastrophic equipment failure. That’s why professionals rely on dependable torque wrench calibration tools.

In this detailed blog, we’ll dive into the essential tools used by professionals, explain how torque wrench calibration works, and explore the types of services available to help you maintain accuracy. We’ll also highlight how companies like HK Calibrations support various industries with advanced tools and reliable torque calibration services.

Table of Contents

Understanding Torque Wrench Calibration

What Is Torque Wrench Calibration? Torque wrench calibration is the process of verifying and adjusting a torque wrench so it delivers a specific amount of torque consistently and accurately. It ensures that the torque applied to fasteners during assembly or maintenance aligns with specified values.

Incorrect torque can result in:

- Damaged components

- Loose connections

- Safety hazards

- Warranty violations

Calibration ensures compliance with industry standards such as ISO 6789, ASME B107, and NATA requirements.

Why Is It Important? Regular calibration helps:

- Maintain the integrity of mechanical assemblies

- Prevent costly errors and rework

- Comply with legal and industry regulations

- Ensure safety in critical systems like engines and brakes

In short, it’s an investment in quality and reliability.

Tools Professionals Use for Torque Wrench Calibration

Professionals and calibration labs rely on specialised tools to deliver accurate results. Here’s what goes into a proper torque calibration setup:

- Torque Calibration Analysers

These are the core of any torque calibration setup. Torque analysers measure the torque output from the wrench under test.

- Digital Torque Testers: Offer real-time readings, programmable thresholds, and data logging. Ideal for high-accuracy environments.

- Mechanical Torque Testers: Simpler but still effective for field applications.

Example: The torque analysers used at HK Calibrations feature peak and first-peak detection modes and support both clockwise and counterclockwise measurement.

- Torque Loading Devices (TLDs)

Torque loading devices are used to apply controlled torque to a wrench. These devices simulate the actual use conditions and help in verifying the wrench’s performance.

Types include:

- Manual TLDs with hand cranks

- Motorised TLDs for consistent torque application

- Torque Transducers/Sensors

Torque transducers convert applied torque into a measurable electrical signal. They are crucial for precise digital calibration setups.

Features to consider:

- High resolution

- Compatibility with data loggers and displays

- Mounting versatility

- Data Acquisition Systems

Modern calibration setups often include software that records data and generates calibration certificates automatically. These systems improve accuracy, reduce human error, and streamline compliance.

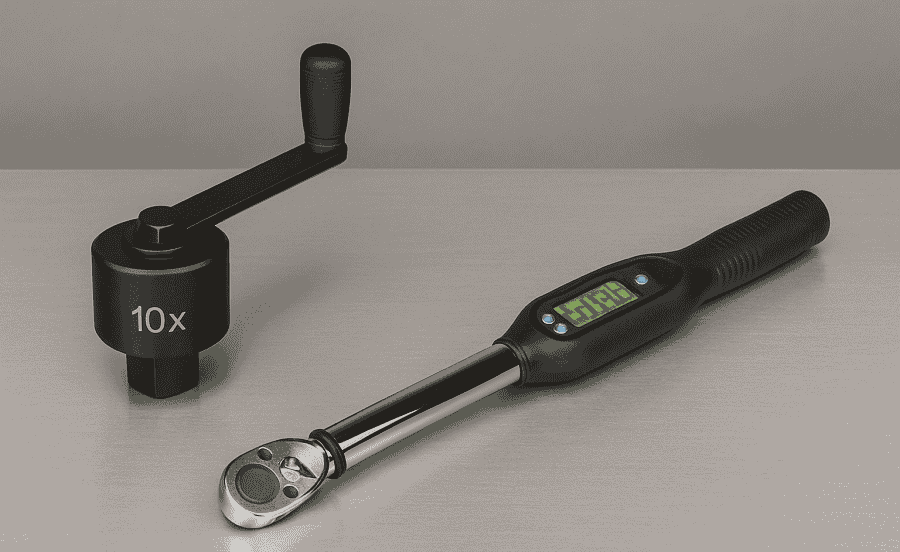

- Torque Multipliers

Used for calibrating high-capacity torque wrenches, torque multipliers allow for higher torque application without excessive physical effort.

- Custom Fixtures and Adapters

Each wrench type may need different attachments for accurate calibration. Professionals often use:

- Open-end adapters

- Ratchet-head mounts

- Square drives and hex adapters

How Torque Wrench Calibration Works

Initial Inspection

Before calibration begins, technicians visually inspect the torque wrench for wear, damage, or contamination.

Setup

Technicians mount the wrench on the calibration rig using the appropriate adapters. They ensure the calibration device (e.g., torque analyser) is zeroed and ready to measure.

Torque Application

Technicians apply torque multiple times at various points (usually 20%, 60%, and 100% of capacity) and record each value.

Adjustment (if needed)

If readings fall outside the acceptable tolerance, technicians adjust the wrench according to the manufacturer’s specifications.

Certification

After completing the calibration, technicians issue a certificate that shows all measurements and confirms the wrench meets standard requirements.

Read More: Torque Multiplier vs Torque Wrench Calibration Differences

Common Types of Torque Wrenches That Require Calibration

Click-Type Torque Wrenches Most common. Make a distinct click sound when set torque is reached. Require regular calibration due to spring mechanism wear.

Beam-Type Torque Wrenches Old-school but reliable. A beam bends as torque is applied, and a pointer shows the value. Less likely to fall out of calibration but still requires periodic checks.

Dial Torque Wrenches Feature a dial display for precise readings. Often used in quality control or lab settings.

Digital/Electronic Torque Wrenches Offer data logging and visual/auditory signals. Require calibration of both torque and the digital system.

Industries That Rely on Torque Wrench Calibration

Automotive Repair Mechanics use torque wrenches for critical components like cylinder heads, wheel nuts, and suspension bolts.

Aerospace Engineering Precise torque is vital for aircraft assembly and maintenance. Errors here can be catastrophic.

Construction Structural bolts in buildings, bridges, and infrastructure must meet exact torque requirements.

Manufacturing and Assembly Lines Ensures product quality and reliability, especially in electronics and heavy machinery sectors.

Mining and Heavy Equipment Huge bolts on machinery need precise tightening to ensure operational safety.

How Often Should You Calibrate Your Torque Wrench?

There is no universal rule, but general guidelines include:

- Every 5,000 cycles

- Every 12 months

- After any significant drop or mechanical shock

Factors like frequency of use, environment, and application criticality can affect this interval.

Choosing a Reliable Calibration Provider

Look for providers that offer:

- Traceable calibration certificates

- NATA or ISO accreditation

- On-site and in-lab options

- Fast turnaround times

- Tool repair and adjustment services

In Brisbane and across Australia, calibration services from experienced providers like HK Calibrations ensure that your torque tools stay compliant and reliable. With a range of torque testers, sensors, and digital equipment, they support industries from automotive to aerospace.