When it comes to competence, toughness, and sustainability, the construction area is always developing, and new resources and know-hows are repeatedly being presented to better these features. One instance of such an invention is the propagation of FRP (Fiberglass-Reinforced Plastic) trench and drain covers, which are transforming the way in which we handle public areas and infrastructure. These covers made of (FRP) provide a unique mix of features, such as resistance to corrosion, lightweight structure, and straightforwardness of maintenance. The appealing application of these materials is another reason for their growing admiration. They are accessible in a broad variety of colours and finishes, creating it best for several architectural styles. Within the scope of this article, we will see into the area of FRP trench and drain covers, checking the benefits that they offer.

The modification of the norm for health and safety

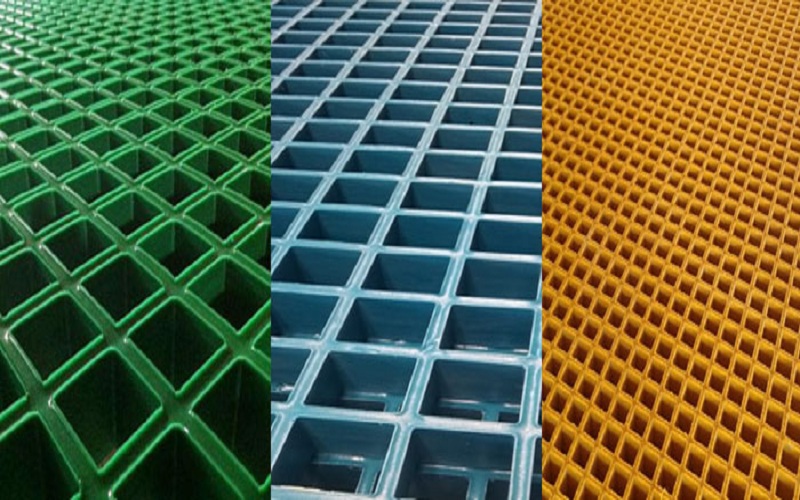

With FRP Grating manufacturers and the world’s largest technology brands specifying Fibrelite covers for new build and retrofit projects, FRP composite trench and manhole covers are quickly becoming the standard for high-performance industries such as airports, commercial ports, leisure cruise terminals, military and defence, power generation (both traditional and renewable), and data centres. Covers made of FRP composite are quickly replacing covers made of metal and concrete.

History of FRP trench and drain covers

The drive of FRP trench and drain started in the mid-20th century. The construction of fiber-reinforced plastic (FRP) began to get importance in the draining cover sector in the 1970s, chiefly in the United States. The benefits of making use of FRP in their goods, such as its resistance to erosion, toughness, and lesser maintenance requirements, became seeming to manufacturers soon after they began to realise these advantages. When the first FRP trench and drain covers were launched, they soon established a reputation for their capacity to survive extreme climatic conditions and intensive usage. This reputation contributed to their widespread adoption.

Throughout several epochs, the use of fiber-reinforced plastic (FRP) here has continued to enlarge, thanks to the progression of making technology as well as the outline of new materials and designs. At present, FRP trench and drain covers are used in a comprehensive variety of applications, starting from the building of residential structures to the construction of large-scale infrastructure installations. With its one-of-a-kind mix of qualities and advantages, fibre reinforced plastic (FRP) continues to be a popular choice, despite the explosion of competing materials and technologies.

When it comes to FRP manhole covers, what kinds of raw materials are required?

Are you aware of the fact that the weight of a manhole cover made of fiber-reinforced plastic (FRP) is one-seventh of the total weight of a standard cast iron cover?

Covers made of FRP are constructed using a combination of the following components:

- The raw fibre glass strands that are used in the moulding process of the FRP covers cause the inherent structure of the covers to harden, allowing them to hold and bear large weights without bending or breaking down.

- A combination of unsaturated resin, often polyester, that is used to assist bind the fibreglass reinforced plastic together in order to give it the correct form is referred to as resin. Through this process, the outside surface of the end product is made to be robust and long-lasting.

- To improve the surface polish and overall strength of the FRP manhole covers, a number of additives are introduced into the manufacturing process. These additives are used to build the product.

- When it comes to the FRP manufacturing process of the manhole covers, these are the fundamental raw materials that are required.

Final Thoughts

When it comes to offering a secure passageway to utility access points while also covering open drains that are resistant to serious accidents, FRP manhole covers are genuinely a guidance you can follow.

On our website, Om Concrete Products, you can also look at our selection of manhole covers made of FRP that may be customised to your specifications.