The latest report by IMARC Group, titled “Prepreg Market Report by Resin Type (Thermoset, Thermoplastic, Epoxy, and Others), Fiber Type (Carbon, Glass, Aramid), Manufacturing Process (Hot-Melt Process, Solvent Dip Process), End Use Industry (Aerospace and Defense, Automotive, Electrical and Electronics, Wind Turbine, Sporting Goods, and Others), and Region 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on the market. The global prepreg market size reached US$ 12.3 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 23.5 Billion by 2032, exhibiting a growth rate (CAGR) of 7.28% during 2024-2032.

Factors Affecting the Growth of the Prepreg Industry:

- Performance Advantages:

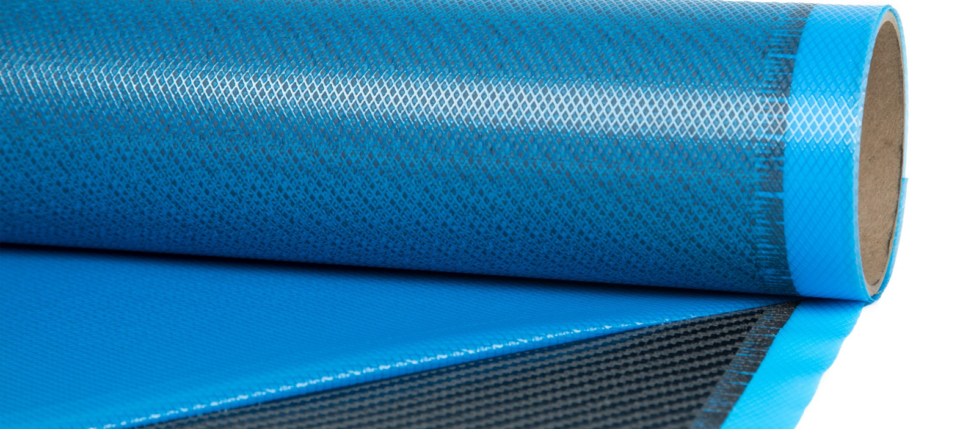

Prepregs offer a multitude of performance advantages over traditional composite materials. One crucial factor is their superior strength-to-weight ratio. By impregnating reinforcement fibers with a precise amount of resin, prepregs achieve a more uniform distribution of the resin throughout the material, resulting in enhanced mechanical properties. This leads to lighter, stronger, and stiffer composite parts compared to those made with wet lay-up or infusion methods. Additionally, prepregs exhibit exceptional dimensional stability, thermal resistance, and fatigue resistance, making them ideal for demanding applications in aerospace, automotive, wind energy, and sporting goods industries. The ability of prepregs to maintain their properties under various environmental conditions further contributes to their growing demand across different sectors.

- Growing Demand in Aerospace and Defense:

The aerospace and defense sector represents a significant driver of the prepreg market. With increasing emphasis on fuel efficiency, aircraft manufacturers are increasingly turning to advanced composite materials such as prepregs to reduce weight and enhance performance. Prepregs offer unmatched strength-to-weight ratios, corrosion resistance, and fatigue properties, making them indispensable in aircraft components such as fuselages, wings, empennages, and interior structures. Moreover, prepregs facilitate complex geometries and streamlined manufacturing processes, which align with the aerospace industry’s demand for lightweight, yet robust, components. The stringent regulatory standards governing aerospace materials also favor prepregs due to their consistency, traceability, and quality control measures. Additionally, the defense sector’s requirements for lightweight, high-strength materials for military vehicles, ballistic protection systems, and unmanned aerial vehicles (UAVs) further drive the adoption of prepregs.

- Technological Advancements:

The prepreg industry continues to benefit from ongoing advancements in manufacturing technologies. Automation and digitization have revolutionized prepreg production processes, enabling higher throughput, improved quality control, and cost efficiencies. Automated lay-up machines, robotic material handling systems, and computer-controlled curing processes streamline production workflows, reduce labor costs, and minimize material wastage. Furthermore, innovations such as out-of-autoclave (OOA) curing techniques and rapid cure resins expand the application scope of prepregs by offering shorter cycle times and lower energy consumption. OOA prepregs eliminate the need for expensive autoclaves, thereby reducing capital investment and operational costs.

For an in-depth analysis, you can request a sample copy of the report: https://www.imarcgroup.com/prepreg-market/requestsample

Competitive Landscape:

The competitive landscape of the market has been studied in the report with detailed profiles of the key players operating in the market.

- Axiom Materials Inc. (Kordsa Incorporated)

- Composites One LLC (Synergy55 Inc.)

- Gurit Holding

- Hexcel Corporation

- Mitsubishi Chemical Corporation

- Park Aerospace Corp.

- SGL Carbon SE

- Solvay S.A.

- Sunrez Corporation

- Teijin Limited

- Toray Industries Inc.

- Ventec International Group

Prepreg Market Report Segmentation:

By Resin Type:

- Thermoset

- Thermoplastic

- Epoxy

- Others

Thermoset dominates the market due to its superior mechanical properties, such as high strength, durability, and resistance to heat and chemicals, making it ideal for a wide range of applications in industries such as aerospace, automotive, and wind energy.

By Fiber Type:

- Carbon

- Glass

- Aramid

Carbon holds maximum number of shares due to its exceptional strength-to-weight ratio, high stiffness, and widespread applications across industries such as aerospace, automotive, sporting goods, and energy.

By Manufacturing Process:

- Hot-Melt Process

- Solvent Dip Process

Hot-melt process dominates the market due to its versatility, efficiency, and ability to produce high-quality prepreg materials across a wide range of applications and industries.

By End Use Industry:

- Aerospace and Defense

- Automotive

- Electrical and Electronics

- Wind Turbine

- Sporting Goods

- Others

Aerospace represents the largest market segment due to its stringent demands for lightweight, high-strength materials to enhance fuel efficiency and performance in aircraft components.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America’s dominance in the prepreg market is attributed to its robust aerospace and defense industries, coupled with significant investments in research and development, fostering the widespread adoption of high-performance materials such as prepregs.

Global Prepreg Market Trends:

An increasing focus on environmental sustainability is driving the demand for prepregs. Unlike traditional composite manufacturing processes, prepreg production typically generates less waste and consumes fewer resources. Moreover, advancements in resin formulations have led to the development of eco-friendly prepregs with reduced volatile organic compound (VOC) emissions and lower environmental impact. As companies strive to meet stringent environmental regulations and consumer preferences for sustainable products, the adoption of prepregs as a greener alternative gains momentum across industries such as automotive, construction, and renewable energy.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=5725&flag=C

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

Browse Our Other Reports:

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic, and technological developments for business leaders in pharmaceutical, industrial, and high-technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology, and novel processing methods are at the top of the company’s expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163