Table of Contents

Understanding the Double Girder EOT Crane

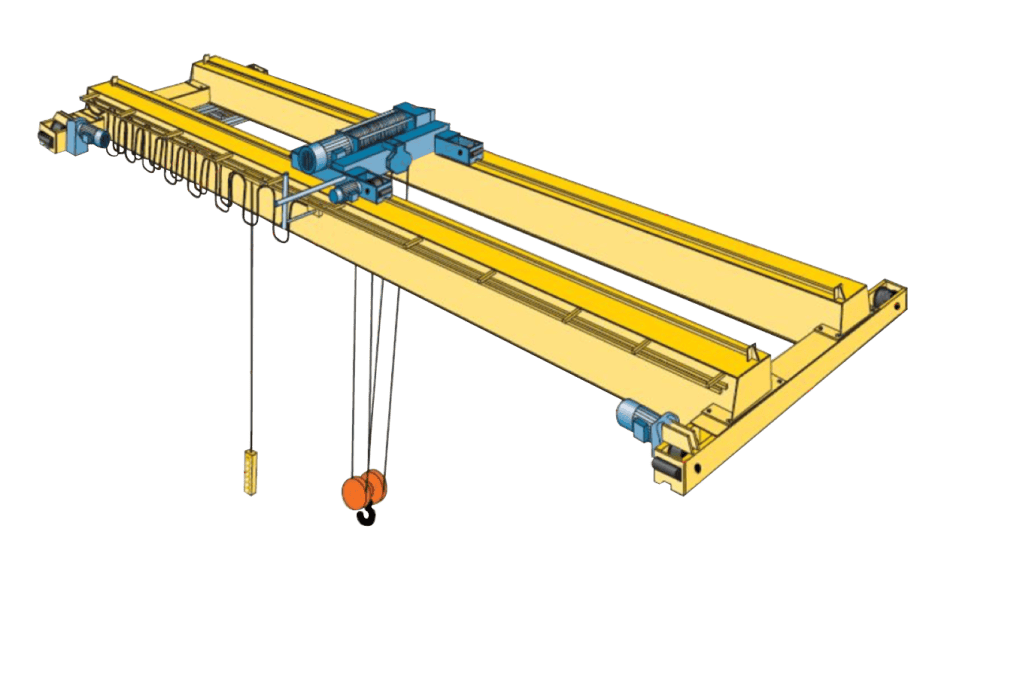

A Double Girder EOT (Electric Overhead Travel) crane is a heavy-duty lifting solution designed for demanding industrial environments. Unlike its single girder counterpart, it has two bridge girders, allowing for higher load capacities, increased span, and superior hook height. These cranes are mounted on end trucks that move along elevated runways, making them ideal for lifting operations that require efficiency, strength, and precision.

From steel plants to heavy machinery workshops, these cranes are the backbone of seamless material handling.

Key Features That Set Double Girder EOT Cranes Apart

Double girder cranes are engineered for durability, performance, and safety. Their distinctive features include:

- High Load Capacity: Typically ranging from 5 tons to 250 tons or more, they are capable of lifting extremely heavy materials with ease.

- Greater Hook Height: The hook can be lifted closer to the crane’s upper limit, optimizing vertical space utilization.

- Wide Span Coverage: Ideal for large factory layouts and heavy-duty applications.

- Customized Configuration: Whether your facility demands flame-proof, weatherproof, or explosion-proof designs—these cranes can be tailored accordingly.

- Advanced Control Systems: Smooth acceleration, deceleration, and positioning are ensured through VFD (Variable Frequency Drive) and PLC-based control panels.

All these features work together to deliver operational excellence in sectors that can’t afford downtime or safety errors.

Industries That Rely on Double Girder EOT Cranes

These cranes are not limited to one industry—they are integral to multiple high-intensity sectors, including:

- Steel and Metal Plants: For handling billets, coils, and finished products.

- Automotive Industry: In assembly lines and heavy machinery movement.

- Power Plants: Especially for turbine and generator installation or maintenance.

- Shipbuilding and Railways: Where large components must be moved with precision.

- Manufacturing Units: Heavy fabrication, large dies, or mold handling made easier.

Each of these industries benefits from the power, control, and efficiency of double girder cranes to streamline operations and enhance safety.

Benefits of Using a Double Girder EOT Crane

Investing in a double girder crane is not just about lifting capacity—it’s about total material handling optimization. Here’s what you get:

- Increased Productivity: Higher lifting speeds and greater spans reduce cycle times.

- Reduced Maintenance Costs: Rugged build and minimal wear components offer long service life with lower maintenance.

- Operational Safety: Anti-collision devices, limit switches, and overload protection ensure safe usage.

- Adaptability: Can be designed for indoor or outdoor use with optional enclosures and weather shields.

- Better Utilization of Floor Space: Because they operate overhead, floor space remains uncluttered and productive.

These cranes bring a fine balance of strength, intelligence, and efficiency to every workspace.

How to Choose the Right Double Girder EOT Crane

Choosing the right crane is critical for both safety and performance. Here are a few factors to keep in mind:

- Load Requirement: Understand the maximum load that needs to be lifted and transported regularly.

- Span and Lift Height: Match the crane’s specifications with your workspace dimensions.

- Frequency of Use: Cranes operating in continuous duty cycles should be rated for Class IV or above.

- Working Environment: Harsh environments need corrosion-resistant or flame-proof components.

- Customization Needs: Do you need auxiliary hoists, tandem lifting, or semi-automatic controls?

A professional consultation can help define the ideal setup to match your plant’s unique operational demands.

The Gajjar Industries Edge in Crane Manufacturing

At Gajjar Industries, the goal isn’t just to manufacture cranes—it’s to provide material handling solutions that last decades. Here’s what makes them stand out:

- Precision Engineering: Every crane is designed using state-of-the-art technology and meets global standards.

- Custom-Tailored Solutions: From design to commissioning, Gajjar Industries works closely with clients to craft cranes that suit their specific workflow.

- Heavy-Duty Components: Motors, brakes, gearboxes, and control systems are chosen for long-lasting performance.

- Pan-India Support: With installations across major industries, their after-sales support ensures smooth crane operation year after year.

Gajjar Industries is not just a supplier—it’s a trusted partner for your lifting needs.

Future Trends in Double Girder Crane Technology

As industries evolve, so do the tools that serve them. Here are some emerging trends in double girder cranes:

- IoT Integration: Real-time tracking of crane performance, load data, and predictive maintenance alerts.

- Energy Efficiency: Regenerative braking systems and efficient motor drives help reduce energy consumption.

- Smart Controls: User-friendly HMI interfaces and programmable control logic for customized operations.

- Lightweight Yet Strong Materials: New fabrication techniques enable stronger cranes with lower structural weight.

Being future-ready is no longer optional—it’s essential. Investing in modern cranes ensures long-term competitiveness.

Lift Your Operations with Confidence

When your production line depends on safe, efficient, and powerful material movement, a double girder EOT crane is the answer. With unmatched load capacity, precision control, and long-term reliability, these cranes are indispensable to modern industries.

If you’re looking for a crane system that can elevate your business to new heights, Gajjar Industries has the experience, technology, and support to make it happen.

Learn more onhttps://www.gajjarindustries.co.in/double-girder-eot-crane/ Or call us at 9328649539