Introduction To Spot Welding

Spot welding is a commonly used method in the production sector, renowned for its capacity to effectively and accurately unite two metal components. Fundamentally, spot welding entails the founding of a robust connection between two metallic surfaces by the application of heat and pressure. The aforementioned process involves the application of a substantial electrical current to the metal components, resulting in resistance-induced heating at the specific location of contact. The thermal energy produced induces the liquefaction of the metal, afterwards undergoing a phase transition to solidify and establish a robust fusion joint.

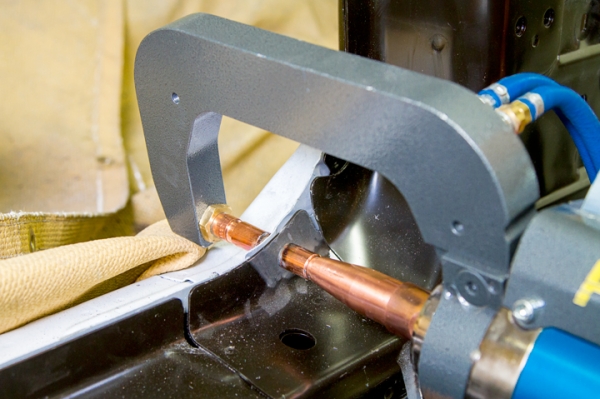

Spot welding machines, often referred to as spot welders, are specialized apparatuses specifically designed for the purpose of executing the spot welding procedure. Welding systems include a power source responsible for generating the necessary electrical current for welding, together with a set of electrodes that facilitate the delivery of this current to the workpieces.

Spot welding machine manufacturers create a localized electric current that flows through the metal pieces, causing them to melt and fuse together, and then utilize this current to connect two or more pieces of metal together at precise areas, often known as “spots.” This process may be used to join two or more pieces of metal together.

Know The Working Of Spot Welding

Spot welding machines have the capability to be operated either manually or in a completely automated manner, depending upon the specific application and production demands. Manual machines are often used in operations on a smaller scale or for the purpose of welding pieces that possess irregular shapes. These machines provide the operator a high degree of flexibility and control. In contrast, automated machines are often used in production settings characterized by large volume, providing advantages such as enhanced speed, precision, and the capacity to consistently reproduce results.

Copper, chromium, zirconium, and low-carbon steel are only some of the metals and alloys that may be used as electrodes in spot welding. Other options include titanium and nickel. Copper, on the other hand, is the most prevalent metal. The melting of the metal and the beginning of the fusion process is caused by the high voltage power supply combined with the intense pressure on the focused area. Because of the low electrical resistance, heat may be generated at the welding position more effectively than in the electrodes themselves.

The Principle Of Spot Welding

Resistance spot welding is a welding technique that utilizes electrical resistance to create heat at the interface of two metal sheets. The thermal energy produced as a result of the electrical current striking resistance causes the metal to undergo a phase change, resulting in the fusion of the two sheets at the point of contact. The aforementioned approach is often executed with a specialized welding apparatus, which exerts pressure on the sheets to secure their position and regulate the electrical current throughout the resistance welding process.

The application of the current is performed with deliberate control by means of the electrodes. The current density is determined by the diameter of the electrode that is in contact with the workpiece. The resistance of the contact area layers is directly influenced by the magnitude of the applied force. In practical applications, the force is manipulated in such a way that thermal energy is promptly created within the area of contact.

Advantages and Applications of Spot Welding

- Spot welding has the advantage of being a quick and efficient way to join two metal sheets together. The automation of the process enables the achievement of high production rates and ensures consistent weld quality. Therefore, it is a highly commendable option for utilization in settings where the preservation of air quality is a matter of importance.

- Due to its cost-effectiveness, spot welding has gathered significant interest among Spot welding machine manufacturers.

- In addition, the use of spot welding techniques generates a welding place that effectively avoids the incineration of undesired sections of work pieces, so guaranteeing the attainment of superior product quality. Spot welders are a very favorable option for firms seeking to optimize efficiency. The thickness of the plates is 1/4 inch, and numerous thin plates are connected simultaneously.

Final Thought

Spot welding is one of the most precise and cost-effective methods for combining metal, but it can only join metals that are no thicker than 3 millimeters. It combines the use of heat with the application of pressure. Electrodes are what apply both electricity and pressure to the spot where welding is taking place.