Working with sheet metal requires precision, efficiency, and the right set of tools. Whether you are a professional fabricator or a DIY enthusiast, one essential piece of equipment you’ll often rely on is the flange tool for sheet metal. This tool plays a critical role in bending, shaping, and creating secure joints, making it indispensable in industries like automotive repair, HVAC, roofing, and general metalworking.

In today’s digital age, tools are not only physical but also virtual. A free online flange tool can help you plan, measure, and design flanges digitally before you even touch the sheet metal. This combination of manual tools and digital solutions allows workers to achieve better accuracy and save time. In this article, we’ll explore what flange tools are, their types, benefits, and how free online tools are changing the game.

Table of Contents

What is a Flange Tool for Sheet Metal?

A flange tool for sheet metal is designed to bend or form flanges along the edge of metal sheets. These flanges can serve multiple purposes, including:

- Strengthening the edge of the sheet.

- Allowing two sheets to be joined together.

- Preparing the sheet for welding or riveting.

- Creating a finished, professional look.

The tool works by applying consistent pressure along the edge of the sheet, ensuring uniform bends without damaging the material. This makes it a go-to tool in fields like automotive panel replacement, ductwork fabrication, and custom metal projects.

Types of Flange Tools for Sheet Metal

Depending on your project needs, different flange tools are available. Here are the most common ones:

1. Manual Flange Tools

These are hand-operated tools ideal for smaller jobs. They’re portable, affordable, and great for hobbyists or repair shops working on light-duty sheet metal projects.

2. Pneumatic Flange Tools

Powered by compressed air, these tools are widely used in automotive body shops. They allow quick and precise flange creation, making them perfect for repetitive tasks such as preparing car panels for welding.

3. Hydraulic Flange Tools

Hydraulic flange tools are designed for heavy-duty applications, where thicker sheets require stronger force. They provide excellent accuracy and are common in industrial settings.

4. Combination Flange and Punch Tools

Some advanced tools combine flanging with punching capabilities, letting users both flange the metal and create holes for rivets or screws in one go.

Benefits of Using a Flange Tool

Using the right flange tool for sheet metal offers several benefits:

- Accuracy: Ensures precise and uniform flanges.

- Efficiency: Saves time compared to manual hammering or makeshift methods.

- Durability: Flanging strengthens sheet edges, reducing wear and tear.

- Professional Finish: Provides clean, smooth edges that improve overall product quality.

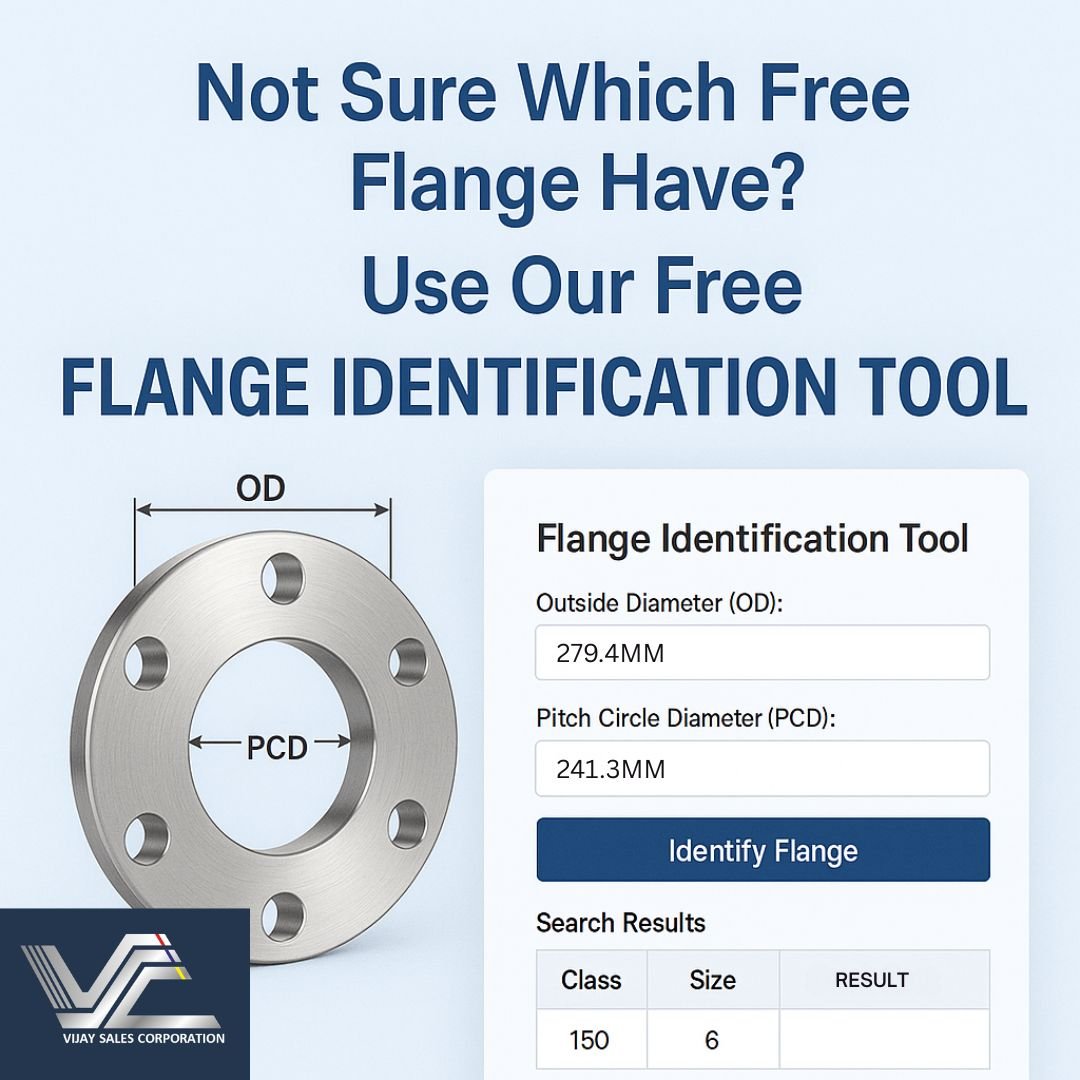

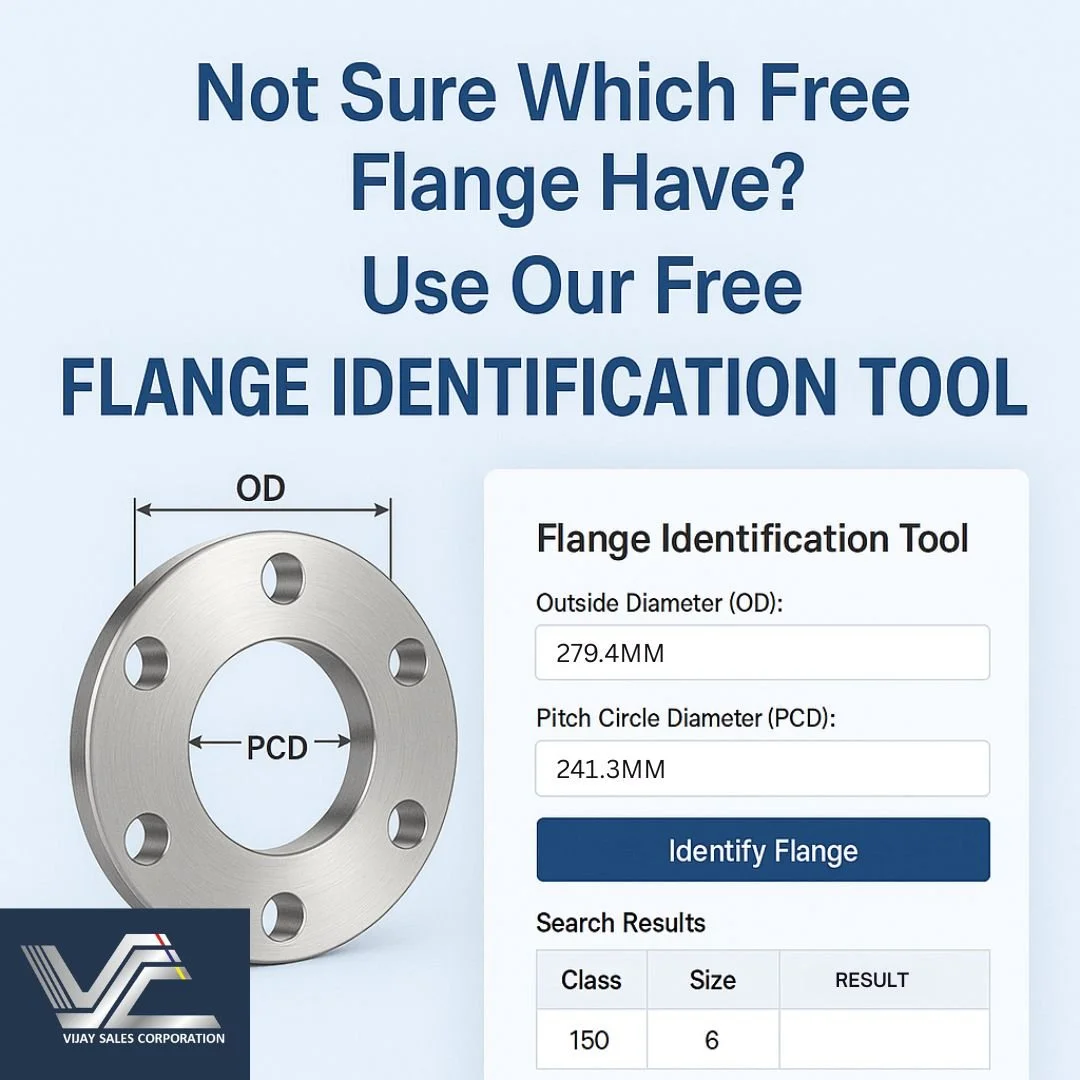

Free Online Flange Tools: A Digital Advantage

While physical tools handle the actual shaping of metal, a free online flange tool provides immense support in the planning stage. These digital tools allow you to input measurements, choose materials, and calculate dimensions before starting the work.

Key Benefits of Online Flange Tools:

- Accurate Measurement Calculations: No more guesswork – you can calculate the exact bend allowance and flange length.

- Design Visualization: Preview the flange design virtually before fabrication.

- Cost Saving: Reduces material wastage by helping you plan correctly.

- User-Friendly: Many online tools are free, easy to use, and require no technical background.

For example, if you are working on an automotive sheet panel replacement, a free online flange tool can help you determine the right flange size before you even touch the physical sheet.

How to Use a Flange Tool for Sheet Metal Effectively

- Measure and Mark: Begin by measuring the exact area of the sheet metal that needs to be flanged.

- Set the Tool: Adjust the flange tool according to the required width and depth.

- Apply Even Pressure: Place the tool on the marked area and apply consistent pressure to create a smooth flange.

- Check Accuracy: Use a caliper or measuring tape to ensure uniform bends.

- Use Online Support: Before starting, run your design through a free online flange tool to confirm accuracy.

Industries That Rely on Flange Tools

Flange tools are versatile and used across multiple industries, including:

- Automotive: For body panel replacement, exhaust systems, and custom modifications.

- Construction: In HVAC ductwork, roofing, and siding.

- Manufacturing: For creating strong joints in machinery and equipment.

- DIY & Crafts: Hobbyists working on custom sheet metal art or small repairs.

Final Thoughts

Whether you are fabricating HVAC ducts, repairing a car body, or working on custom sheet metal designs, having the right flange tool for sheet metal is crucial. It ensures accuracy, saves time, and delivers professional results. At the same time, leveraging a free online flange tool enhances your workflow by allowing you to plan ahead, minimize errors, and reduce waste.

By combining physical tools with digital resources, metalworkers can achieve superior results while saving both time and money. If you’re serious about improving your sheet metal projects, investing in the right flange tool and using online design aids is the smartest way forward.