In today’s competitive manufacturing landscape, optimizing production processes has become crucial for businesses seeking to maintain their edge. One technological advancement that has revolutionized assembly line operations is the Assembly Winder Dual Speed Motor. These sophisticated motors offer unprecedented flexibility and efficiency, making them indispensable components in modern industrial applications.

Table of Contents

Understanding Assembly Winder Dual Speed Motor Technology

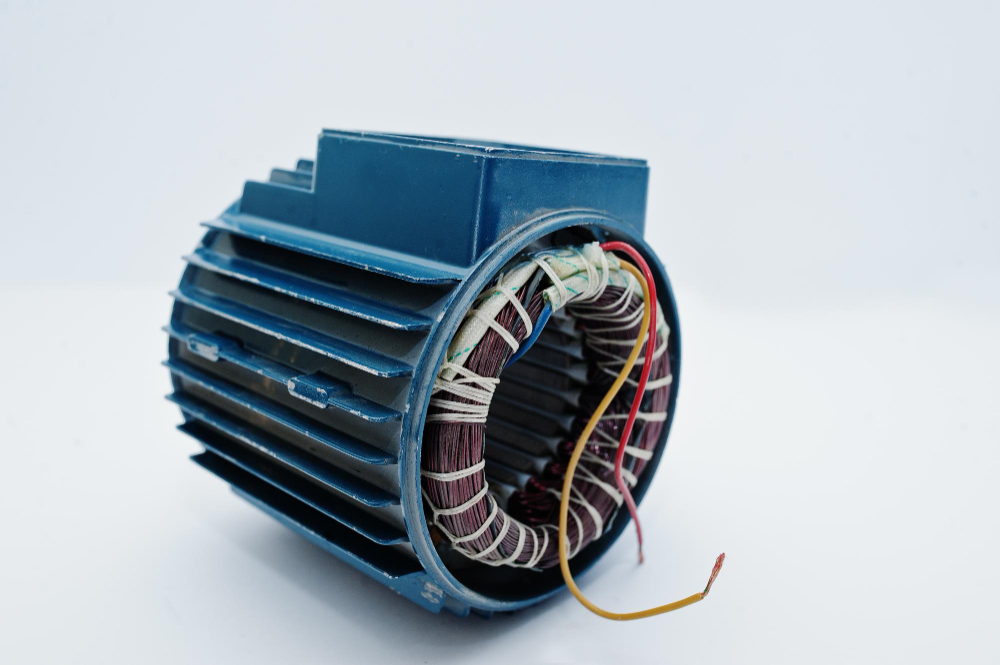

An Assembly Winder Dual Speed Motor represents a significant leap forward in motor design, combining two distinct operating speeds within a single unit. This innovative approach allows manufacturers to adapt their production processes to varying requirements without the need for multiple motor installations or complex speed control systems.

The fundamental principle behind these motors lies in their unique winding configuration. Unlike conventional single-speed motors, Assembly Winder Dual Speed Motor variants feature specially designed windings that can be electrically reconfigured to operate at two predetermined speeds. This versatility makes them particularly valuable in assembly line applications where different stages of production may require varying operational speeds.

Key Advantages of Dual Speed Motor Systems

Enhanced Production Flexibility

The primary benefit of implementing an Assembly Winder Dual Speed Motor is the remarkable flexibility it provides to manufacturing operations. Production managers can seamlessly switch between high-speed operations for bulk processing and low-speed precision work for delicate assembly tasks. This adaptability eliminates the need for multiple motor systems, reducing both capital investment and maintenance requirements.

Energy Efficiency Optimization

Modern Assembly Winder Dual Speed Motor units incorporate advanced energy management features that automatically optimize power consumption based on operational demands. When running at lower speeds, these motors consume significantly less energy compared to single-speed alternatives operating under variable load conditions. This efficiency translates directly into reduced operational costs and improved environmental sustainability.

Reduced Maintenance Requirements

The robust construction of Assembly Winder Dual Speed Motor systems contributes to their exceptional longevity and reliability. By eliminating the need for external speed control devices, these motors reduce the number of potential failure points in the system. This simplification results in lower maintenance costs and increased uptime for critical production equipment.

Applications Across Industries

Textile Manufacturing

In textile production facilities, Assembly Winder Dual Speed Motor technology has proven invaluable for winding operations that require precise tension control. The ability to switch between speeds allows operators to handle different yarn types and weights effectively, ensuring consistent quality across diverse product lines.

Packaging Operations

Modern packaging lines benefit significantly from dual speed motor technology. During setup and changeover procedures, operators can utilize low-speed operation for precision adjustments, then switch to high-speed mode for maximum throughput during production runs.

Automotive Assembly

The automotive industry has embraced Assembly Winder Dual Speed Motor solutions for various assembly line applications. These motors excel in applications requiring both high-speed conveyor movement and precise positioning capabilities, such as component installation and quality inspection stations.

Technical Specifications and Performance

Motor Configuration Options

Contemporary Assembly Winder Dual Speed Motor designs typically offer speed ratios ranging from 2:1 to 4:1, providing substantial operational flexibility. Common configurations include 1200/2400 RPM and 1800/3600 RPM options, allowing engineers to select the most appropriate speed range for specific applications.

Control System Integration

Modern dual speed motors seamlessly integrate with programmable logic controllers (PLCs) and other automation systems. This compatibility enables sophisticated control strategies that can automatically adjust motor speed based on production requirements, sensor feedback, or predetermined timing sequences.

Installation and Maintenance Best Practices

Proper Installation Procedures

Successful implementation of Assembly Winder Dual Speed Motor systems requires careful attention to electrical connections and mechanical mounting. Proper phase sequence verification ensures correct rotation direction at both speed settings, while adequate ventilation prevents overheating during extended operation periods.

Preventive Maintenance Strategies

Regular inspection of motor bearings, electrical connections, and cooling systems maximizes the operational lifespan of dual speed motors. Scheduled maintenance programs should include vibration analysis, thermal imaging, and electrical testing to identify potential issues before they result in costly downtime.

Future Developments and Innovations

The evolution of dual speed motor technology continues with advancements in materials science and electronic control systems. Next-generation motors promise even greater efficiency improvements and enhanced integration capabilities with Industry 4.0 manufacturing systems.

Conclusion

Assembly Winder Dual Speed Motors represent a proven solution for manufacturers seeking to optimize their production processes while minimizing equipment complexity and operational costs. Their versatility, efficiency, and reliability make them an excellent investment for businesses committed to maintaining competitive advantages in today’s demanding manufacturing environment.

By carefully selecting and implementing these advanced motor systems, companies can achieve significant improvements in productivity, energy efficiency, and operational flexibility that directly impact their bottom line performance.To Learn More https://atlaselectrical.in/dual-speed-motor/ or call us on +91 98240 03939.