In recent years, the printing industry in Rajahmundry, along with the broader global market, has been experiencing major shifts due to the digital revolution. One of the most pressing challenges traditional printing businesses face is the rapid migration toward digital media. More businesses and individuals are now relying on digital content, reducing the need for printed materials like newspapers, brochures, and even notebooks.

As a result, printing companies are struggling to maintain volume-based revenue. While some segments, such as packaging and labels, continue to grow, others like booklets and flyers are seeing declining demand. To remain relevant, many businesses are adopting hybrid models that combine digital printing with traditional methods, but this requires significant investment in new technology, staff training, and process adaptation.

Table of Contents

How Do Rising Raw Material Costs Affect Notebook Manufacturers?

One of the key concerns for notebook manufacturers in India, including those operating in Rajahmundry, is the increasing cost of raw materials. Paper, ink, glue, and binding materials have all become more expensive due to fluctuations in global supply chains, environmental regulations, and inflation.

Smaller and medium-sized enterprises, like many notebook producers, often operate on thin margins and cannot absorb these increased costs without impacting pricing or profitability. Companies like Sri Rama Binding Works have had to reassess their supplier contracts and explore local sourcing strategies to keep costs under control. Despite these efforts, maintaining consistent product quality while staying competitive in price is an ongoing challenge.

Is Sustainability a Real Challenge for the Printing Sector?

Yes, environmental sustainability has become a crucial issue for the printing industry. As public awareness around environmental conservation grows, there’s increased pressure on printing companies to reduce their carbon footprint and adopt eco-friendly practices.

From using recycled paper and vegetable-based inks to implementing waste management systems, there’s a strong push toward green printing. However, for many players in the printing industry in Rajahmundry, adopting these measures involves higher operational costs. Balancing sustainability goals with profitability remains a difficult line to walk, especially for notebook manufacturers competing in a price-sensitive market like India.

Are Technological Advancements Difficult to Keep Up With?

The fast pace of technological evolution is both a blessing and a burden for the printing industry. On the one hand, new digital printers, automated binding machines, and AI-based design tools offer increased efficiency and improved product quality. On the other hand, these innovations come with high capital costs.

For notebook manufacturers in India, staying up to date with these technological trends can be financially draining. Moreover, integrating new systems requires staff retraining and changes in workflow management. Even a well-established name like Sri Rama Binding Works has had to evolve its machinery and processes to match the market’s changing expectations and maintain a competitive edge.

What About Customization Demands From Clients?

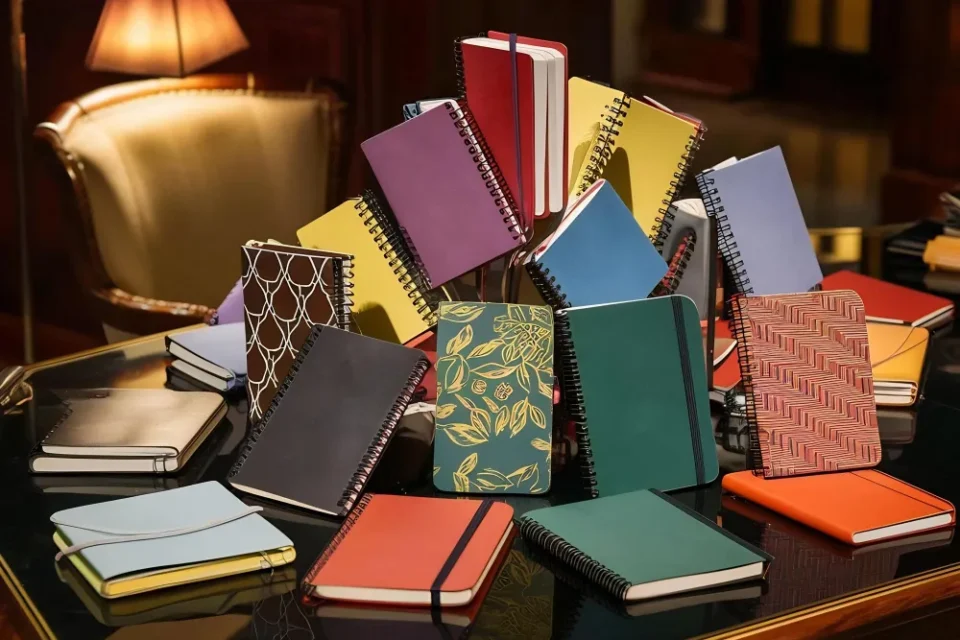

Today’s customers want more than just standard notebooks or printed materials. Customization has become a key differentiator in the market. Whether it’s a corporate client looking for branded notebooks or a school needing unique covers, the demand for tailored products is at an all-time high.

This shift requires notebook manufacturers and printers to be highly flexible and agile in their production processes. Meeting these expectations consistently without causing production delays or cost overruns is a significant challenge. In the printing industry in Rajahmundry, this is even more pronounced, as clients are becoming more quality-conscious while expecting faster turnaround times.

Does Skilled Labor Shortage Limit Growth?

Despite being a labor-intensive industry, the printing sector often struggles to attract and retain skilled talent. With younger generations more inclined toward IT and service sectors, fewer people are entering the printing trade. This talent shortage affects production timelines, quality control, and the ability to scale operations.

Notebook manufacturers in India have been particularly affected by this. With large orders requiring precision and speed, the lack of experienced workers can become a bottleneck. Training programs are necessary but add to operational expenses and time investment. Businesses like Sri Rama Binding Works have focused on upskilling their existing workforce, but attracting new talent remains a long-term challenge.

Are Distribution and Logistics Still a Pain Point?

Getting the finished product into the hands of customers efficiently is another hurdle for the printing sector. Inconsistent transportation services, rising fuel costs, and delays in supply chains all affect delivery schedules. For notebook manufacturers in India, who often deal with orders across multiple states or even internationally, managing logistics can become a complicated affair.

For the printing industry in Rajahmundry, the situation is no different. While the town is well-connected by road and rail, last-mile delivery and coordination with vendors can sometimes lead to unexpected delays and customer dissatisfaction. Investing in a reliable logistics partner and tracking system is essential but not always feasible for smaller companies.

Is Market Competition Forcing Price Wars?

The Indian printing market is highly fragmented, with a mix of local shops, regional players, and large-scale manufacturers. This intense competition often leads to undercutting and price wars. While this benefits the customer, it places a heavy burden on businesses striving for sustainability and profitability.

To survive, companies must differentiate themselves through quality, customer service, and innovation. Sri Rama Binding Works has stood the test of time in Rajahmundry by offering value-added services like custom designs, prompt delivery, and bulk order handling—yet even established names are not immune to the effects of pricing pressures.

Are Government Regulations Becoming Tougher?

The government has been increasing regulatory oversight on environmental practices, worker safety, and product labeling standards. While these regulations are necessary for ethical and sustainable business operations, they add an extra layer of complexity for manufacturers.

Compliance requires additional documentation, investment in safety gear, emission control mechanisms, and sometimes even a complete revamp of manufacturing processes. For businesses in the printing industry in Rajahmundry, navigating this regulatory landscape without losing focus on core operations is yet another daily challenge.

Final Thoughts: How Can the Industry Move Forward?

Despite the numerous challenges, the Indian printing industry—including notebook manufacturers in India and players from regions like Rajahmundry—continues to show resilience. Innovation, adaptation, and customer-centric strategies are the keys to future success.

Businesses like Sri Rama Binding Works are proving that with the right mix of technology, talent, and tradition, it’s possible to thrive even in a tough market. By embracing digital tools, streamlining production, focusing on sustainability, and offering customized solutions, printing companies can not only overcome today’s hurdles but also unlock new growth opportunities in the years ahead.