Medical device packaging machines are essential for ensuring the safety and sterility of medical equipment. These machines help package medical devices securely, protecting them from contamination and damage during transport and storage. Whether you are a manufacturer or involved in healthcare, understanding how these machines work and the importance of proper packaging can make a big difference in product quality and safety.

Table of Contents

Types of Medical Device Packaging Machines

Medical device packaging machines come in various types, each serving a unique purpose. Choosing the right machine depends on the type of device and packaging required.

Thermoforming Machines

Thermoforming machines create packages by heating and molding plastic films around the device. These machines are ideal for creating secure, custom-shaped packages. Thermoforming ensures that each device is well-protected and easy to access.

Blister Packaging Machines

Blister packaging is commonly used for small medical devices, pills, and tablets. This machine creates a hard plastic shell for each item, protecting it from damage and contamination. Blister packaging also makes it easy to see each device through the packaging, helping users identify it at a glance.

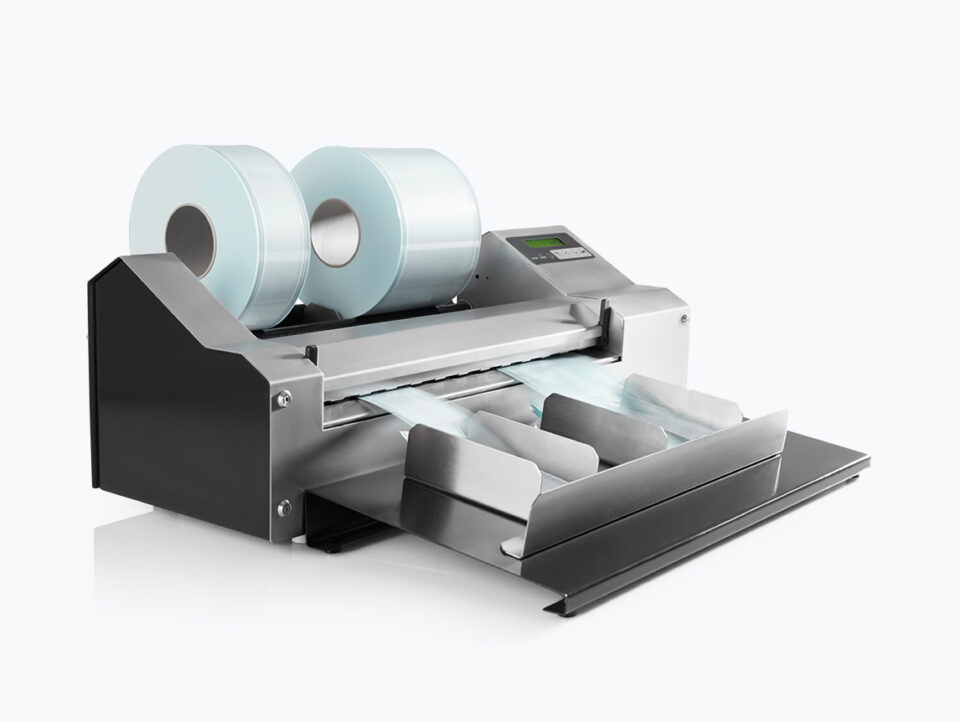

Pouch Sealing Machines

Pouch sealing machines are designed for devices that require flexible packaging. This machine seals the device within a durable pouch, ideal for items like surgical tools and instruments. Pouches offer an easy-to-open design, making them suitable for fast-paced healthcare environments.

Material Choices for Medical Device Packaging Machines

The materials used in medical device packaging machines play a crucial role in maintaining sterility. Choosing the right materials is essential to ensure that the packaging meets safety standards and protects the device.

Tyvek and Medical-Grade Paper

Tyvek and medical-grade paper are widely used in medical packaging. These materials are durable and offer strong barrier protection, making them ideal for keeping medical devices sterile.

Plastics and Films

Various types of plastic films are used to create a secure, sealed environment for devices. Plastics provide excellent visibility and are resistant to tears, making them a popular choice for many manufacturers.

Importance of Sterilization Compatibility

Medical devices need to remain sterile, which is why medical device packaging machines must be compatible with sterilization methods like ethylene oxide (EtO), gamma radiation, and autoclaving. Packaging materials must withstand these processes without breaking down or contaminating the device. Selecting sterilization-friendly packaging ensures that devices are safe for use directly from the package.

Regulatory Standards for Medical Device Packaging

Compliance with global standards is mandatory for medical device packaging machines. ISO 11607 sets guidelines to ensure that medical packaging meets industry requirements. Adhering to these standards helps manufacturers guarantee that their packaging offers the necessary protection and maintains sterility until the device is used.

Testing and Validation of Packaging Quality

Regular testing and validation are essential for ensuring the reliability of medical device packaging machines. Testing helps manufacturers confirm that each package provides a secure barrier and retains sterility. Common tests include seal strength tests, microbial barrier assessments, and leak testing. Validating these processes is critical in meeting regulatory standards and maintaining high-quality packaging.

Conclusion

Understanding the role of medical device packaging machines is crucial in the healthcare sector. By selecting the right machine, materials, and processes, manufacturers can ensure that medical devices remain safe, sterile, and effective. Compliance with standards and regular testing further strengthens the reliability of these machines, making them indispensable for safeguarding healthcare products. Proper packaging ultimately plays a vital role in protecting the device and the end user, enhancing overall healthcare quality.