Despite the fact that cotton swabs are a common household item, have you ever given any thought to the manufacturing process behind them? Among the components that are used in the manufacturing of cotton swabs, cotton swab paper sticks are among the most often utilized. The cotton tip is equipped with a shaft that is both robust and simple to grasp thanks to its use. Within the scope of this blog article, we will see the whole lifetime of cotton swab paper sticks, beginning with the gathering of the raw materials and ending with the manufacturing of the finished product.

Here we will also dig into the manufacturing process and concentrate on the numerous processes that are involved in the production of these vital products. You will get a fascinating understanding of the lifetime of cotton swab paper sticks by reading this post, regardless of whether you are a consumer with an inquisitive nature or an insider in the business.

Extracting Cotton For Use In The Manufacturing Of Paper

The harvesting of cotton is the first step in the journey of a cotton swab paper stick. This is a procedure that is strongly based in agricultural traditions as well as current farming practices. Cotton is grown in wide fields, where the fluffy white bolls that hold the cotton fibers develop under the sun. Cotton plants are carefully nurtured in their environments.

Farmers tend to their crops with great care, ensuring that they are placed in the best possible growth circumstances by means of irrigation, fertilizer, and insect control. After the cotton bolls have reached their full maturity, they are carefully removed from the plants, which marks the beginning of a laborious procedure that will be used to extract the precious fibers.

In order to harvest cotton for the purpose of paper manufacture, a combination of human labor and mechanical processes is required. Through the use of a number of methods, including ginning machines, which separate the seeds from the fluffy fibers, workers are able to carefully separate via seeds. Following harvesting, the cotton undergoes further processing in order to provide the raw material that is required for the creation of paper that in turs can create cotton swabs.

Cotton’s journey from harvest to paper stick is a memorial to the dedication of farmers, laborers, and artisans engaged in every stage of the process. From the sun-kissed fields to the industrial facilities, the journey of cotton highlights the craving of all those involved.

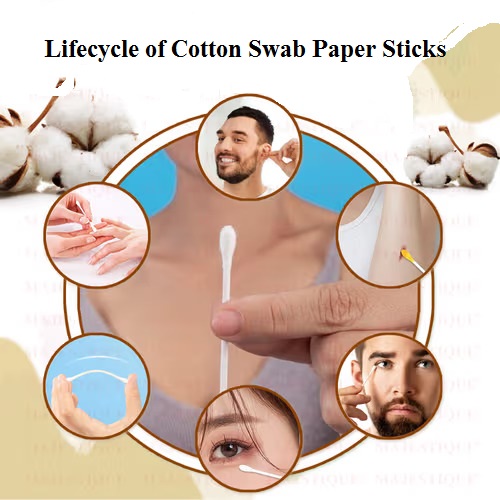

There are often multiple steps involved in the life cycle of a cotton swab paper stick, beginning with the extraction of raw materials and ending with their disposal. The following is an outline of the several stages that a cotton swab paper stick goes through:

- The first step in the process is called “Raw Material Extraction,” and it entails the extraction of raw materials that are required for the production of the paper stick. In most cases, this entails the collection of timber from forests that are maintained in a sustainable manner, with trees being replanted in order to guarantee a renewable resource.

- During the manufacturing process, the wood that has been gathered is first processed in a facility in order to generate the paper sticks. For the purpose of ensuring that the wood is acceptable for use in cotton swabs, this procedure entails cutting, shaping, and sometimes treating the wood.

- Packaging and Distribution: After the paper sticks have been created, they are packed and then delivered to a variety of merchants and customers.

- Use: Cotton swabs are used by customers for a variety of functions, including personal hygiene, the application of cosmetics, cleaning, and the creation of crafts.

Conclusion

Thus, consider switching to eco-friendly alternatives or reducing the use of cotton swabs altogether to lessen the burden on the environment.