Choosing packaging solutions matters to your organization. You want to provide your customers with the best medical products. The packaging needs to work to ensure that outcome. But how do you choose which packaging solution should be at the top of your list? Here are five key factors to help you decide and point you in the right direction. Once you go through this list, you’ll find it easier to filter your options.

Table of Contents

Sterilization

Sterilization is one of the most important things you’ll need to consider when you shop for medical packaging products. If you’re looking for medical papers that work for both Et0 sterilization and radiation, you likely won’t run into any problems. However, if you are looking for medical papers that can work with steam sterilization, that’s a potential drawback. Look for medical papers that hit the mark. Go a step further and research papers that meet your sterilization requirements.

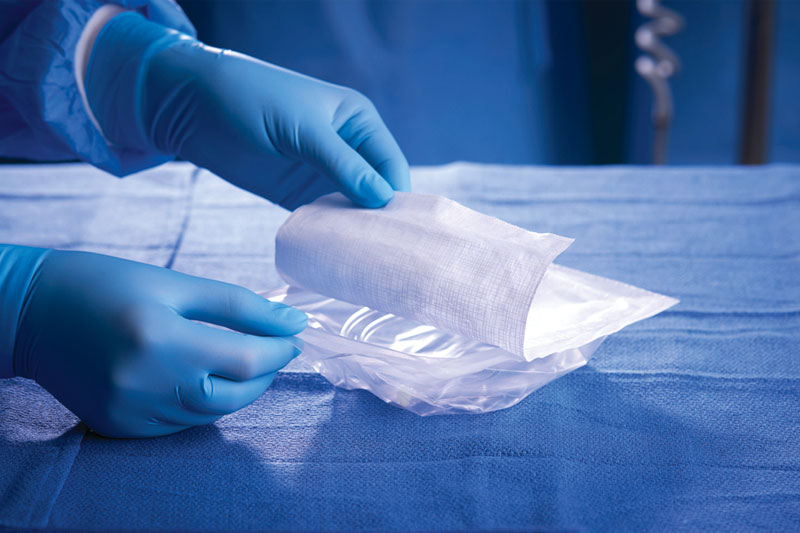

Device Protection

When you shop for medical device packaging products, find out if the packaging can meet your sterilization needs. What device will you package? That’s another critical question. The device will determine your packaging solutions to an extent. If the device is heavy, that will strain the material of the packaging, so it must be durable. Sharp devices may puncture the packaging. You’ll need a material that can prevent those design failures and issues. While altering the device’s position in the material may help reduce the risk of damage, you still need packaging that you can reinforce.

Sealing

Sealing the package prevents contamination and exposure. So, the stronger the seal, the better it is for your products. At least, that’s what most companies believe. But a stronger seal can also be at a greater risk of fiber tear. That puts you in a pickle. The best packaging solutions don’t require the strongest seals. You merely need to assess how strong the seal needs to be. Choose options that provide seal protection that’s right for the level of strain it puts on your products. If you still require a stronger seal, consider treating the surface like heat sealing the paper to ensure a strong seal. That helps prevent fiber-free peeling.

Pack Size

What is the best size for the pack? Larger packs are often used for heavier devices since they require more protection. However, that puts more pressure on the seals. A smaller pack has fewer seal problems.

Also, larger devices bear more stress on the paper, which can result in tearing. The same thing happens to long packs. You can use heavier paper or reinforced options to solve the problem. Those are some of the questions and considerations you must consider for packaging solutions.

Market Costs and Expectations

Think about the target market for the device and the packaging. Will your buying audience want better packaging? Do they demand a premium presentation or appearance of the paper? Or do they want budget-friendly options? Stay on top of your budget but ensure you don’t compromise patient safety to achieve that. Choose packaging solutions that protect the integrity of your products.