The use of Coordinate Measuring Machines (CMM) in production has increased to meet the demands of precision and accuracy in manufactured parts. CMMs ensure high-quality products, which is critical in today’s competitive market. Therefore, it’s essential to maintain the accuracy and performance of the CMMs. CMM calibration is the process of verifying and adjusting the accuracy of CMMs. In Connecticut, KES Machine Tools has been leading the field of CNC repair, CNC retrofits, and laser calibration since 2000. This article will highlight how KES Machine Tools can help manufacturers optimize their production quality with CMM calibration.

Table of Contents

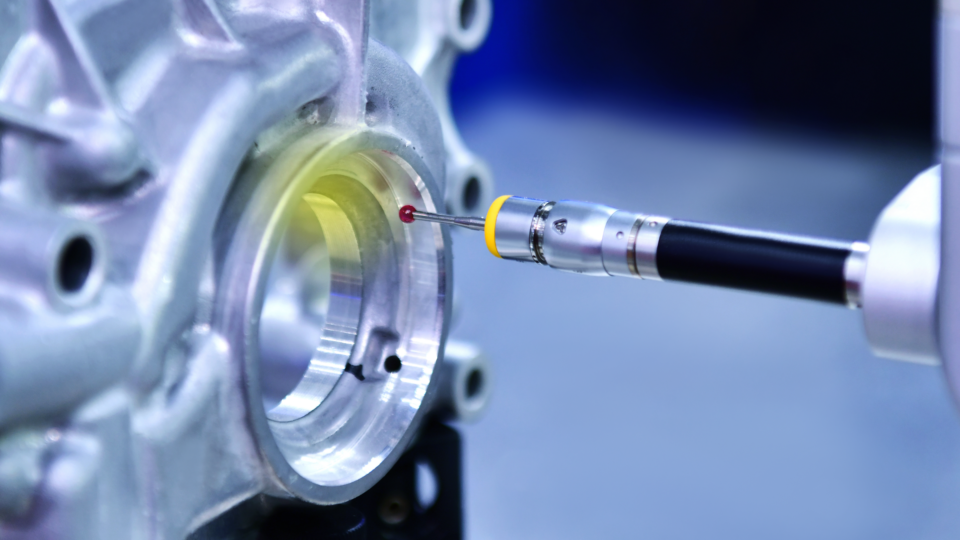

1. Importance of CMM Calibration

CMMs play a crucial role in ensuring that products meet the required specifications. The accuracy of CMMs can be affected by various factors such as wear and tear, temperature changes, and even physical damage. Calibration helps to ensure that the CMMs remain accurate and reliable. Proper calibration of CMMs can help to minimize errors and ensure consistent and repeatable results. Regular calibration also reduces the risk of costly reworks and rejects, which can lead to production delays and customer dissatisfaction.

2. KES Machine Tools’ Expertise in CMM Calibration

KES Machine Tools is a reputable company that specializes in CNC repair, retrofits, and laser calibration. Their team of experts has years of experience in providing reliable and accurate CMM calibration services. KES Machine Tools uses state-of-the-art equipment and software to ensure that the calibration is precise and consistent. They follow strict procedures and standards to ensure that the CMMs meet the required specifications.

3. Benefits of KES Machine Tools’ CMM Calibration Services

One of the main benefits of using KES Machine Tools for CMM calibration is the accuracy and precision of the calibration. The team of experts at KES Machine Tools ensures that the CMMs are calibrated to the required standards, ensuring that the manufactured products meet the specifications. Additionally, KES Machine Tools’ calibration services can help to reduce downtime and increase productivity. Regular calibration ensures that the CMMs remain accurate and reliable, minimizing the risk of costly reworks and rejects. This helps to reduce production delays and ensures that customers receive their products on time.

4. KES Machine Tools’ CMM Calibration Process

KES Machine Tools’ CMM calibration process involves a series of steps to ensure that the CMMs are calibrated accurately. The first step involves inspecting the CMM to identify any physical damage or wear and tear. The team of experts then proceeds to perform a software and hardware check to ensure that the CMM is functioning correctly. They then carry out a series of tests to verify the accuracy of the CMM. If any adjustments are required, the team of experts will adjust the CMM to the required standards. Once the calibration is complete, KES Machine Tools provides a detailed report of the calibration results.

5. KES Machine Tools’ Laser Calibration Services

In addition to CMM calibration, KES Machine Tools also provides laser calibration services. Laser calibration is a precise and accurate method of calibrating machines, ensuring that they meet the required specifications. KES Machine Tools’ team of experts uses state-of-the-art equipment and software to provide reliable and accurate laser calibration services. Laser calibration helps to ensure that machines are accurate and reliable, minimizing the risk of costly reworks and rejects.